The rotary evaporator with motor lift is one of the most crucial types of rotary evaporators. This is the unit that rotates the evaporation flask or the container with the substances being evaporated. The motor varies depending on different rotary evaporators.

In most cases, the engine determines the kind of materials that the rotary can work with. For example, a rotary evaporator that has a motor lift is suitable for substances that require close control regarding the boiling time, temperatures and even the pressure.

What is Rotary Evaporator with Motor Lift?

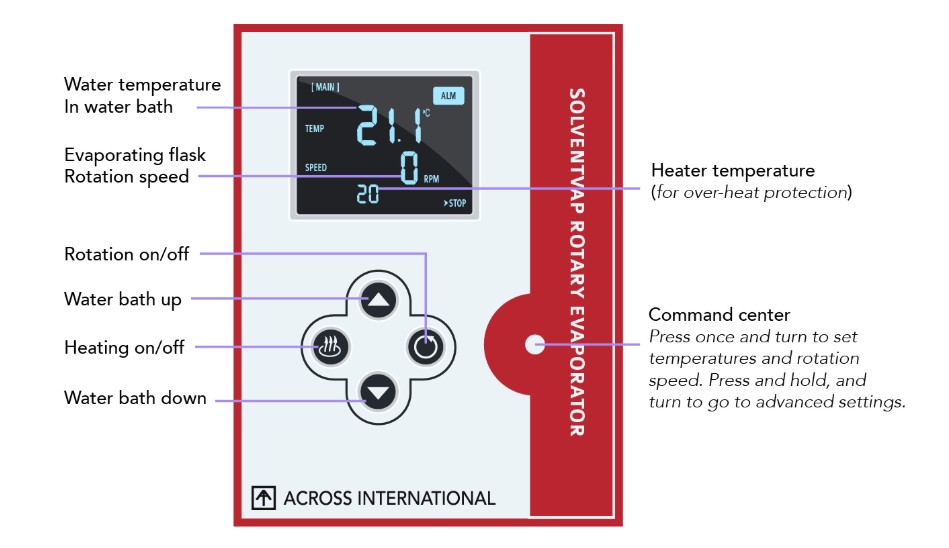

The rotary evaporator with the motor lift are digitally controlled, and it automatically shifts to change the process in case of an emergency such as power outage. The motor is digitally set and displayed on the LCD screen for easy control. Just one touch of the electric shift, the device immediately moves to either up or down direction. This kind of rotary evaporator can be used with chemicals that require both high and low heat.

It is quite easy when controlling the pressure and the heat needed with the one shift mechanism of the motor. The device is ranked as one of the first performing industrial rotaries since it has an efficient condenser that ensures excellent recovery of the substances.

They come with heating baths that are made non-corrosive material; therefore, you can remove the bath for cleaning purposes. In the case of a power outage, you can still get hold of the evaporating process with the equipped lift upshift. The vacuum condenser is made of glass material which helps prevent the liquid from stagnating or even flowing back. It has a universal power supply and can work with a power source ranging from 100 to 240 VAC.

>>Rotary Evaporator Definition

The Features of Rotary Evaporator with Motor Lift

1. Motorized heating bath

One of the features that make this evaporator ideal for substances that require high and low heat/ pressure is the motorized bath. It automatically lifts to control the amount of heat needed based on the elements heated.

2. Large LCD screen

It is easy and comfortable to monitor the evaporation process through the equipped LCD.

3. PID temperature control

The rotary evaporator is equipped with an inbuilt PID temperature controller which accurately controls the amount of temperature needed to ensure good heating.

4. Durable bath

The heating bath of this evaporator is crafted with high quality and durable materials that are resistant to corrosion. It does not rust even after prolonged exposure to harsh chemicals and heat.

5. Enhanced bath cover protector

The enhanced cover improves the safety of the evaporating flask and the materials used. This is because it provides equal distribution of temperature inside the evaporation flask. Note that this mechanism also helps to prevent heat loss.

6. Digital motor lift

Whether you are working on the substance that needs high or low heat, the digitalized motor lift makes it easy to control the temperature and pressure required. It automatically lifts and lowers depending on the substance used. Note that the digital lift occurs if there is an electric power outage.

7. Easy to use

Working with this apparatus in various industrial settings is straight forward. The digital LCD screen and motor lift help to control the pressure and heating temperatures needed.

8. Modular design

This type of rotary is designed in a modular form, which makes it easy to use and control. The parts that are used in the evaporation process are easy to remove for cleaning purposes.

>> Rotary Evaporator Parts and Their Functions

The Specifications of WKIE Lab Rotary Evaporators

| Model | R-1010 | R-1020 | R-1050 | RE-1002 | RE-2002 | RE-3002 | RE-5002 |

| Rotation Flask | 10L | 20L | 50L | 10L | 20L | 30L | 50L |

| Bath Lift | Motor Lift | Motor Lift | Motor Lift | Hand Lift | Hand Lift | Hand Lift | Hand Lift |

| Condenser | Glassware: Vertical with dual-spiral glass tubing | Glassware: Vertical with dual-spiral glass tubing | Glassware: Vertical with dual-spiral glass tubing | Glassware: Vertical with dual-spiral glass tubing | Glassware: Vertical with dual-spiral glass tubing | Glassware: Vertical with dual-spiral glass tubing | Glassware: Vertical with dual-spiral glass tubing |

| Flask Rotation Speed | 0-120rpm | 0-120rpm | 0-120rpm | 0-120rpm | 0-120rpm | 0-120rpm | 0-120rpm |

| Motor Power | 250W | 250W | 250W | 180W | 180W | 250W | 250W |

| Receiving Flask | 5L | 10L | 20L | 5L | 10L | 20L | 20L |

| Vacuum Degree(Ultimate Pressure) | 20mbar | 20mbar | 20mbar | 20mbar | 20mbar | 20mbar | 20mbar |

| Heating Power(customizable) | 4KW | 4KW | 6KW | 3KW | 5KW | 8KW | 8KW |

| Temp. Control | PID from main heater, ON/OFF Control | PID from main heater, ON/OFF Control | PID from main heater, ON/OFF Control | PID from main heater, ON/OFF Control | PID from main heater, ON/OFF Control | PID from main heater, ON/OFF Control | PID from main heater, ON/OFF Control |

| Safety | Over-temp and fuse protections | Over-temp and fuse protections | Over-temp and fuse protections | Over-temp and fuse protections | Over-temp and fuse protections | Over-temp and fuse protections | Over-temp and fuse protections |

| Glass Material | High borosilicate glass 3.3 | High borosilicate glass 3.3 | High borosilicate glass 3.3 | High borosilicate glass 3.3 | High borosilicate glass 3.3 | High borosilicate glass 3.3 | High borosilicate glass 3.3 |

| Power Source | 220V 1ph, 50HZ(Customized: 110V) | 220V 1ph, 50HZ(Customized: 110V) | 220V 1ph, 50HZ(Customized: 110V) | 220V 1ph, 50HZ(Customized: 110V) | 220V 1ph, 50HZ(Customized: 110V) | 220V 1ph, 50HZ(Customized: 110V) | 220V 1ph, 50HZ(Customized: 110V) |

Rotary Evaporator with Motor Lift VS. Rotary Evaporator with Hand Lift

- Differences

Both of these rotaries are essential for various industrial uses, but their feature differs, which may also affect the kind of substance to use. Rotovap with motor lift is digitally controlled, and it makes it super easy for one to manage the evaporation process. On the other hand, the rotary equipped with hand lift is manually controlled with hands. The evaporator with a motor shift is ideal for substances that require both low and high heats.

On the side, the hand lift rotary evaporator can only be used on materials that need low temperature and pressure. The rotary evaporator with hand lifts features a double cooler seal which ensures no content is tuck on the glass flask, thus improving the condensation. The rotary with motor lifts is used in large scale industries such as pharmaceutical, recycling industries, and even dying industries. On the other hand, hand lifts are suitable for simple experiments and are highly recommended for learning institutes.

- Similarities.

Although these two rotaries vary in uses and some features, they are both easy monitoring of the evaporation process. And they are suitable for use with chemicals and substances that need low heat and pressure. They are easy to use and features high-quality material that cannot be destroyed by the harsh chemicals from the elements used.

Conclusion.

Rotary evaporator with motor lift is a versatile device applied in different industries. It is easy to use and control, especially in terms of heat usage. These devices are compatible with flasks with a capacity of up to 5 liters. Make sure to clean the glass vacuum of the rotary before using it as guided by the manufacturers. The other type of rotary evaporator related to motor lift is the hand lift evaporator, which operates.