Molecular Distillation

Short path distillation from Wkie Lab enables short feeding time as well as high quality outputs.

OFFERING THE BEST SELECTION OF QUALITY LABORATORY MACHINES

Wkie Lab Molecular Distillation For Purchase

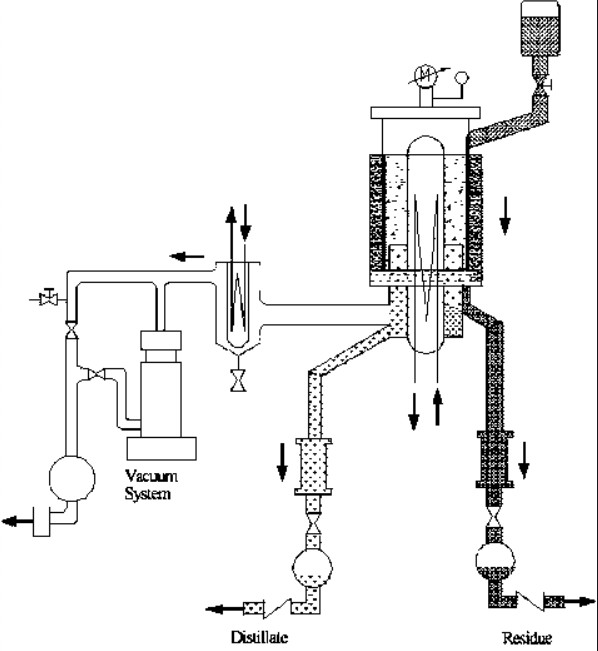

Molecular distillation is a short-term vacuum distillation, depicted by incredibly low vacuum pressure, 0.01 Tor, which is performed using molecular static. And, it is a procedure for dividing, cleansing, and converging common elements, compound, and thermally sensitive atoms, for example, nutrients and polyunsaturated fats. A temporary show of the distillate describes this procedure to high heats in a high vacuum. The distillation section is used at a short distance between the evaporator and the condenser about 2 cm.

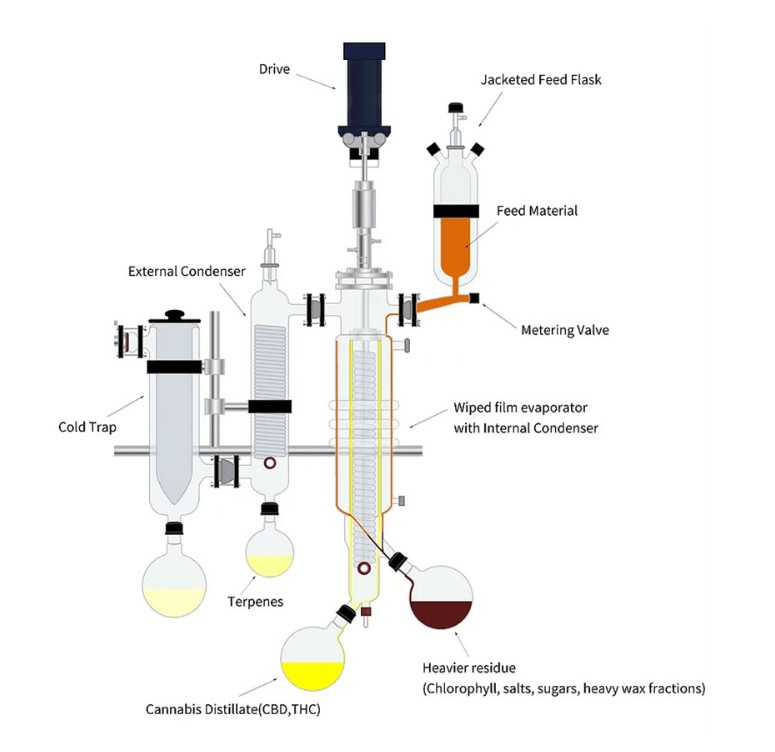

The Structure of WKIE Lab Molecular Distillation

- Jacketed feeding flask with manual feeding valve

- Magnetic driving stirring

- Jacketed glass barrel with an internal condenser

- Cooling coils cold trap

- Heating circulator for jacketed feeding vessel

- Heating circulator for jacketed glass barrel

- Heating/Cooling Circulator for internal condenser

- Vacuum pump

- Control system

- Continuous collection module (Distillate and Residue)

- Gear pump for automatic and continuous feeding

- External condenser for collecting Terpenes

- Cooling circulator for external condenser

- Cooling circulator for cooling coils cold trap

WKIE Lab Molecular Distillation Design

In molecular distillation, fluids are found in the free molecular current system. That means that the open path of atoms is practically similar to the size of the device. The vapor phase never applies noticeable pressure on the material to be evaporated, so dissipation speed is never dependent on demand. The movement of molecules lies in the apparent path since they no longer form a continuous gas. In this way, the short path between the hot surface and the cold surface is necessary. By hanging a hot plate attached to a feed layer next to a cold plate with a path that can be seen in the middle, we can achieve this.

WKIE Lab Molecular Distillation Equipment Features

Feeding System

- Jacket designing

- Multiple entries of material

- High Borosilicate glass 3.3

- Feed insulation system available

Short path evaporator with internal condenser

- Made of high Borosilicate glass 3.3 easy for viewing multiple entries of material

- PTFE blades, which is high temp resistance and anti-corrosive

Receiving System

- The receiving system can be upgraded for non-stop operation.

Cold Trap

- The main components are fabricated in Borosilicate glass to enable observation of product properties like foaming, fouling and film distribution on the heated shell during distillation

Controller Console

- VFD controlled stirring motor with digital speed disply.

- High accuracy vacuum display to monitor the pressure during operation.

- Temperature controllers for heating the inlet/outlet pathways and keeping liquid moving.

Molecular Distillation Manufacture – WKIE Lab

As one of molecular distillation manufacturers, WKIE Lab is professional and experienced in producing experiment equipment, and we are always committed to providing our customers with the best service and products.

On the one hand, we have professional teams with experienced engineers and highly-trained workers; and on the other hand, we have well-equipped factories for manufacturing equipment in accordance with customers’ meets. Additionally, the kinds of WKIE Lab equipment are various; from molecular distillation to glass reactors, you can always find the one you need, From the construction to now, our equipment has been sold to more than 50 countries, and have won high praise and good reputation from clients.

Contact for Cheapest Price: For more information on molecular distillation for sale, just contact us and we will provide top quality products and services for you wholeheartedly.

The Highlights of WKIE Lab Molecular Distillation for Sale

1. Short feed time.

A rotating scrubber pushes the material onto a warming surface, and the liquid of the material carefully twists falls and leaves the warming surface, the material that comes off the heated surface was quickly assembled by cooling the condenser, this method should limit contact material time and surface insulation.

2. Low evaporation temperature.

In high vacuum conditions, short-distance distillation equipment through a material and liquid distributor, a scrubber are assembled so that the material is evenly distributed over the heating surface, reducing weight qualification that is delivered to the static liquid surface material.

As a result, the unstable will evaporates. Steam will be dense in a discrete condenser, and the liquid will be removed as a generous thing or sent to the associated stage. This strategy is experienced warm parcel technique with the least amount of rot and the highest quality.

3. No leaking mumble.

The short path of molecular distillation is the free evaporation of the outside of the liquid layer, which is transmitted to under low weight. Since there is no separated air in the liquid, all liquid cannot be percolated during distillation, therefore without spraying.

4. Not risky, harmless, environmentally friendly, without development, can get real and safe things.

The molecular distillation system is a professional procedure using warm packages with minimal disruption and exceptional quality. So it is most reasonable to use CBD for oil production or things of healthy well-being and so on. He can abandon the shackles of engineering procedures and maintain the necessary qualities.

5. High skill of evaporation, strong adaptability, necessary actions.

The rotary scrubber makes the material evenly distributed over the insulating surface in the form of a film; the liquid film reliably maintains a state of high unevenness, which animates the movement of the glow to reduce the incident glow.

The immediate structure that supports cleaning, the ability to start and stop, suitable for certain combinations, unpredictable minimum difficult age.

| Model | MD-060 | MD-080 | MD-100 | MD-150 | MD-200 |

| Effective evaporation area (m2) | 0.06 | 0.1 | 0.15 | 0.24 | 0.35 |

| Barrel diameter (mm) | 60 | 80 | 100 | 150 | 200 |

| Feed rate(g/hr) | 250-500 | 500-750 | 750-1500 | 1500-3000 | 3000-5000 |

| Yield at end of 8-10 hr.day | 1-3 Liters | 2-5 Liters | 3-8 Liters | 6-15 Liters | 10-20 Liters |

| Motor power (W) | 90 | 120 | 120 | 120 | 200 |

| Maximum speed (rpm) | 0-500 | 0-500 | 0-500 | 0-500 | 0-500 |

| Distillate receiving flask | 1L | 1L | 2L | 3L | 5L |

| Recycle receiving flask | 1L | 1L | 2L | 3L | 5L |

The Application of Molecular Distillation

The molecular distillation has aspects to avoid the toxic quality problem that occurs in strategies that use solvents as an isolation operator, as well as minimize misfortunes due to warm decomposition. What’s more, it can be used in a continuous feeding process to harvest distillate without breaking the vacuum.

Application of Molecular Distillation Technique in Food Products

Molecular distillation can be applied in different parts of the food production. That is particularly reasonable for separating heat-sensitive and useful oxidation materials by dividing and purifying unsaturated fats.

1. Carotene Extraction

Carotene is a type of nutrient used in food. Today more people use ordinary carotene instead of industrial carotene. The whole process of producing industrial carotene needs triple molecular distillation; carotene-containing products can reach 40%.

2. Fat Extraction

Monoglyceride is widely used in the food emulsion business. The forensic molecular distillation technique is a typical case of that much-announced process study. The entire investigation process, similarly, has a directly investigated molecular distillation process. The most widely recognized assembly methods are to consolidate the era of the first oil solution of presumably low content of monoglyceride-containing products by 40 percent, 7 percent glycerol, and 35 percent glycerides.

Molecular distillation can be used to produce synthetic nutrients like vitamin E. Another advanced use in the synthesis of nutrients E is the derivation of acetic acid. The process contains 10% of the refractive point results and about 2% of the resin.

3. Amide Obtainment

Unsaturated fatty amide is used as an emulsifier in physical work. It has anticorrosive reactions and amines that are obtained from the response. Even though the registration requirements for high product quality, but low performance, for example, 98.5% quality, the frequency of not more than 88%, the use of molecular distillation rate up to 94%, It can reduce half of the waste.

4. Purification of Natural Essential Oils

Solid spices such as unpredictable substances, high heat sensitivity, and regular recovery and purification processes, generally three-way molecular distillation, first-class oxidation, second-level odor or purification, bleaching, or third stage are used. For example, rose oil after molecular distillation can settle in the smell is not pleasant, deep shading and wax content of the top, so that the added value improved significantly.

5. Capsaicin Purification

The red pepper dye-containing 1% to 2% soluble, after two-stage molecular distillation processing, the products broke the remaining quantity that meets the quality requirements. Also, similarly, you can achieve the successful division of capsaicin and pigment, which contains 10% capsule. From the general supercritical pepper by molecular distillation processing, the allicin content can be increased to 25% or more.

The use of molecular distillation can improve product quality, system reliability, short maintenance time, and low biological consumption, and can be used in the usual process of technology improvement and new advances in the process. Even though molecular distillation equipment is more expensive than standard distillation equipment, current vacuum technology to balance the system is high performance. The high efficiency and decrease of workers can reduce distillation costs, and the degree of decrease is undoubtedly more than the price of the machine.

Application of Molecular Distillation Technique in Fine Chemicals

There are several applications of molecular distillation techniques in fine chemicals. The process is developed to allow separation of compounds which can be denatured at high temperatures. Lowering of pressure creates a partial vacuum where the boiling points of substances are reduced drastically. The method has been helpful in the separation of the following compounds:

1. Extracting Tocopherols from Soya Sludge

Tocopherols have low boiling points. They can be denatured when the temperature goes too high. The application of molecular distillation has proved to be highly effective in the extraction of the compounds. It preserves the chemical composition of the tocopherols in the extraction process.

2. Production of Lactic Acid

Too high temperatures can lead to denaturing of lactic acid. In the production of lactic acid, molecular distillation is applied to extract lactic acid from raw materials. It is used due to its ability to preserve the quality of lactic acid in the extraction process.

3. Paraffin Wax Extraction

The application of molecular distillation is used to extract paraffin wax. Temperatures can be lowered after lowering the pressure to achieve the desired temperature for the removal of the paraffin wax.

4. Monoglycerides Extraction

In the process of monoglycerides extraction, molecular distillation is applied. It is among the few processes you can use to get the monoglycerides from their raw materials. The method of molecular distillation aims at lowering the temperatures, which leads to the successful extraction of the monoglycerides.

5. Omega‐3 Fatty Acids

The extraction of omega -3 fatty acids from fish fats involves the application of molecular distillation. The fatty acids are sensitive to high temperatures. As a way of preventing their damage, the experts include the use of molecular distillation. It is a process that consists of the use of the latest equipment, which subjects the fatty acids to the most appropriate temperatures as a way of extracting the oils.

The Application of Molecular Distillation Technique in the Pharmaceutical Industry

The application of molecular distillation techniques in the pharmaceutical industry (also known as ‘short path’ distillation) is observed when two heat intolerant compounds need to be safely separated. Most organic and silicon compounds, for instance, cannot be exposed to temperatures greater than 250ºC without risk of serious degradation.

Instead of relying on traditional equipment like low pressure-packed or atmospheric distilling towers, molecular distillation uses high vacuum stills to convert heat from condensation processes into a viable catalyst for radiant heat release to the surface layer on the evaporator.

The distance between the condenser and evaporator must be kept short and clear of impediments. It is this close proximity and the application of much cooler distilling temperatures, which keeps organic compounds from disintegrating when heated.

Thus, within the pharmaceutical world, molecular distillation is most commonly used for the purposes of solvent swapping, separating chemical compounds, crystallization, purification from volatile impurities, and dry from water.

Solvent swapping, for example, plays a vital part in the creation of many different medicines. Often, multiple solvents are needed to create a particular medicinal substance, but they may be needed at different times and varying stages. Solvent swapping, via molecular distillation, is a way to add and extract compounds to active pharmaceutical ingredients without negatively affecting their temperature and solubility limits. The ‘swap’ happens when an active solvent is carefully extracted using distillation techniques and replaced with a new solvent.

Solvents are essential to the formulation of medicines such as penicillin, aspirin, topical ointments, and cough syrups and tinctures.

Some other applications are as follows:

- Adding compounds/solvents to active ingredients to create concentrated pharmaceutical solutions

- Upgrading of pharmaceutical substances for artificial feeding

- Incorporating blending ingredients to creams, ointments, and lotions to achieve a smooth consistency

- Dissolving pharmaceutical substances in active solutions to create topical pet products

Equipment Checklist for Pharmaceutical Distillation

Molecular distillation equipment of this type comes in a variety of sizes. Within the fine chemicals industry, units are typically sized anywhere from pilot size to one or two stages for feed rates of 5-450 l/h. Each has an independent vacuum group, chilling group, hot oil heating system, and control cabinet.

Short path molecular distillation units must include all of the following components:

- Storage Vats

- Feeding/Drawing Off Pumps

- Trap Condenser

- Evaporator with Integrated Condenser

- Chilling Group

- Heating Group

- Multi-Process Vacuum Group

- Control Cabinet

In cases where the melting point of either compound is very high, the distillation unit’s apparatus must also be outfitted with double-layered heated sleeves. These are required for its pumps, tanks, pipes, and valves.

Invest in a high-quality stirrer for your distillation unit’s evaporator. As well as ensuring compounds are evenly heated, a stirrer reduces the thickness of the liquid films, accelerates the condensation of vapors, and helps to split residues from distillates.

When purchasing molecular distillation equipment, look for evidence of rigorous laboratory testing. Before shipping, we will perform a series of tests to ensure high performance and efficiency.

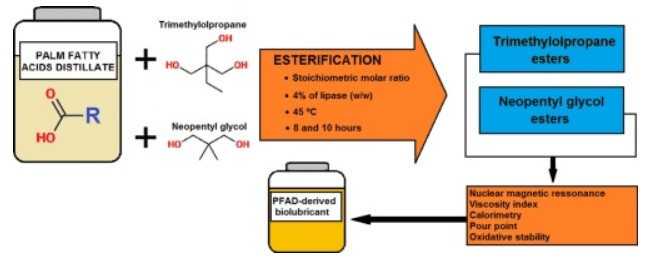

Why People Extract Tocotrienols from Palm Fatty Acid Distillates By Using Molecular Distillation

Crude palm oil contains approximately 1% of the secondary components, including carotenoids and vitamin E, which contribute to the safety and properties of palm oil. Palm oil is seen as the best source of vitamin E, and the content of vitamin E in palm oil is new because it consists of tocotrienol instead of tocopherol. Fatty palm distillates are the unpredictable natural material recovered as a valuable result of the regeneration of palm oil. Some processes have been proposed to improve tocopherols and tocotrienols from fatty palm distillates.

For this separation process, it is essential to develop a treatment procedure to eliminate the values of tocotrienol and other secondary components of palm fatty distillates using molecular refining. Molecular refining occurs at low temperatures and reduces the problem of pyrolysis. The high vacuum also produces the oxidation that can occur in front of the air. The evaporation rate is controlled by the speed of the particles that escape the free surface of the liquid and is fixed to the condenser. The effects of the feed flow rate and the refining temperature depend on the extraction of secondary components of bony fatty distillates on fixations, distribution factors, and relative fluctuations.

The separation of Tocryrenols from Palm Fatty Distillates approached most of the severe traits at low temperatures and fell dramatically as the temperature increased. For ideal conditions of tocotrienol extract with high return and maturation, it is crucial to determine the effect of treatment agents on the extraction of secondary components of fatty spirits of pityriasis. That is because they are installed in the liquid and vapor phases. That can help in detecting the behavior of the selected elements in the evaporation process. That will help to determine the evaporation and instability properties of tocotrienol and secondary elements, apart from fatty palm distillate.

Squalene is a compound commonly known as a natural cancer prevention agent used in restorative and pharmaceutical projects. As the primary source of squalene, shark liver oil, has become increasingly restricted in its accessibility, efforts have been made to eliminate squalene from other sources.

Research has found that one of the wastes provided by the palm oil industry, in particular, is palm oil distillate products. It contains squalene, among other valuable compounds, as Indonesia is perhaps the largest producer of palm oil. The large number of fatty distillates consumed in the palm was exceptionally intriguing in response to meeting the current demand for natural squalene. In this investigation, the extraction of squalene from palm fat distillation products is simplified by the extraction process of different stages, where the results show a marked increase in squalene yield.

Molecular Distillation CBD

Molecular distillation CBD is the process of separating compounds in cannabis. Cannabis is known to have several compounds that have different effects on the body. The experts apply molecular distillation to get pure forms of the compounds. Most compounds in CBD are unstable at high temperatures.

As a way of separating them through molecular distillation, the experts expose them to different temperature ranges at low pressure. By lowering the pressure, the boiling point of the various ingredients in CBD reduces. The application of the molecular distillation makes it easy to separate the molecules in CBD at different temperatures.

How is Molecular Distillation CBD Performed?

The process is undertaken in a controlled environment. Molecular distillation equipment is applied to carry out the operation. The machine allows regulation of temperature and pressure. The molecules in CBD are known to separate at specific temperatures. The lowering of the pressure makes it possible to attain the low temperatures at which the particles separate.

Lowering pressure

When pressure is lowered, it is possible to attain boiling points at low temperatures. It is necessary to keep the temperatures low because high temperatures can lead to the disintegration of the molecules. The process involves close monitoring of pressure. The equipment allows regulation of the temperatures. The temperature is maintained at different boiling points of the particles separating. With time, the molecules evaporate, after which they are collected in a jar.

Cooling the molecules

After the boiling point has been maintained, the particles will boil and evaporate, after which they will condense on the colder parts of the apparatus. Cooling is performed to get the cold molecules. Molecular distillation CBD is a process applied to attain pure molecules of CBD at low temperatures. It is a highly reliable process of obtaining several molecules from CBD, which are applied in different products.

Why Do People Choose to Use Molecular Distillation Equipment to Produce Fish Oil?

People who want to do fish oil business are always confused when they are selecting the best way to extract fish oil. After all, there is a wide variety of processing methods, types, and dosages. One standard option is molecularly distilled fish oil. This process may be a little more expensive than others, but it provides a range of health benefits and reduces the risk of toxicity, making it an excellent choice for many consumers.

Initially, oil from fish was rendered from the liver and fatty tissues of the fish using heat. This process produces a relatively pure oil that contains all the same substances as the fish itself. The rendering process has been used since at least the late 18th century and is best known as the process by which cod liver oil was made. However, the oil produced by rendering alone tends to produce indigestion and gastrointestinal problems in some people.

Molecular distillation is a newer technology that is responsible for the better tasting, purer oils on the market today-distilling the oil extracted from fish after rendering removes the unpleasant taste. It also allows the oil to be easier on the digestive system and takes out the saturated fats and cholesterol, producing a supplement that is better for the cardiovascular system.

Moreover, the molecular distillation process also reduces the risk of contamination by a heavy metal too dangerous chemicals. So the distilled oil from the fish is healthier even safer, also when practiced in large doses. That oil might cost the little more than oils made utilizing the older process, but it gives excellent results. The distilled oil extracted from fish also usually has reliable levels of omega-3 fatty acids and other essential nutrients, so using molecular distillation technology to extract fish oil is a good solution for the people who want to do fish oil business.

Molecular Distillation Principle

The molecular distillation principle is based on lowering boiling points of molecules by reducing the pressure. The molecules in essential oils and CBD tend to be denatured when exposed to high temperatures. The process of molecular distillation aims at lowering the pressure of the environment where the oils are put as a way of reducing their boiling points. The apparatus used in molecular distillation aims at lowering the pressure as a way of creating a vacuum where the compounds are separated. By lowering the pressure, it is possible to get different compounds.

1. The Purity of products in molecular distillation

It is essential to use the molecular distillation process as a way of getting the products at a high purity level. The process is very useful in getting different substances. It aims at preventing the disintegration of the unstable molecules in oils and CBD as a way of maintaining their health effects. There are several active ingredients in CBD. The application of molecular distillation aims at preserving the potency of the active elements. It is a way of making the elements highly effective when applied.

2. Elements involved in molecular distillation

There is a need to control temperature and pressure in the process of molecular distillation. The method of separating the different ingredients in oils relies on temperature and pressure. The boiling point of the various ingredients is known. In most cases, the temperatures are low. The reduction in pressure helps in reducing the boiling points. Temperate is controlled to allow the molecules to evaporate, after which they collect at cold regions of the equipment.

The process leads to the separation of highly volatile compounds in the CBD products. It can be applied on a small scale or even in big industries depending on the size of the apparatus applied. Many users prefer it due to the high purity levels realized upon the application of the principle.

Molecular Distillation Process

The molecular distillation process involves lowering pressure before heating the molecules to their boiling points. In most cases, the process is used to separate natural oils, which can become unstable when subjected to high temperatures. Special equipment is used to lower the temperature of the natural oils before they are subjected to heat.

There is a need to monitor the temperature of the ingredients being heated carefully to avoid exposing them to the temperature, which can lead to damaging their chemical compositions. The molecular distillation process is common in the field where it is effectively applied to separate CBD oils.

Steps Involved in the Molecular Distillation Process:

1. Control of Pressure

The process is carried out under controlled pressure. The pressure in the environment where the compounds are heated is reduced. The reduction in pressure makes it possible to lower the boiling points of the ingredients being separated. A decrease in the boiling point of the unstable elements in the compounds makes it possible to separate them.

2. Heat Control

Prior research is carried out to know the boiling point of different molecules in the CBD or any other natural oil which is being separated. Temperature is controlled to ensure the products can be separated. There is a need to monitor the heat changes closely to avoid incidences where they can be too high to damage the molecules. There is special equipment in the market that can be applied to carry out the molecular distillation process. You can rely on them to carry out the process.

There is a need to get the products when they are pure. For example, a product such as CBD oil tends to be highly effective when it is obtained in pure form. The application of molecular distillation plays a significant role in purifying the natural oils. It preserves their chemical composition because the temperature is controlled.

The Importance of Molecular Distillation Technolgy

Although we always use molecular distillation equipment on many occasions, how many of us know about the molecular distillation technology refining process – what is its significance, why is it process so crucial?

I will make the process of extracting fish oil as an example to explain the meaning of molecular distillation technology.

We all know that today, because of the increase in agricultural and industrial waste being dumped into the ocean waters, the aquatic life residing in ocean waters is full of contaminations like mercury, lead, arsenic, PCBs, etc. This means that fish oil that contains the oil extracted from the cold-water fish caught from such polluted ocean waters should undergo proper refining methods during their manufacturing process to filter out all the unwanted toxins.

This is where the molecular distillation technology refining process plays a vital role. This is the only known refining process that removes all the harmful chemicals from the oil-based on their molecular weight. This process also ensures that the oil is of pharmaceutical grade quality.

Another factor that plays an important role is the freshness in fish oil. Freshness is measured with the degree of oxidation of oil; higher is the oxidation, more unfortunate is the quality.

We know that fish are prone to oxidation; if fish were not appropriately handled before oil could be extracted from them, they start decaying, resulting in rancid oil. Consumption of this oxidized oil has many side effects – rancid odor, fishy burps, long-lasting metallic after taste, and increased free radical activity in the body.

Thus, in the process of extracting fish oil, molecular distillation technology plays a crucial role. Similarly, in other processes of extracting purifications, molecular distillation technology is also significant.

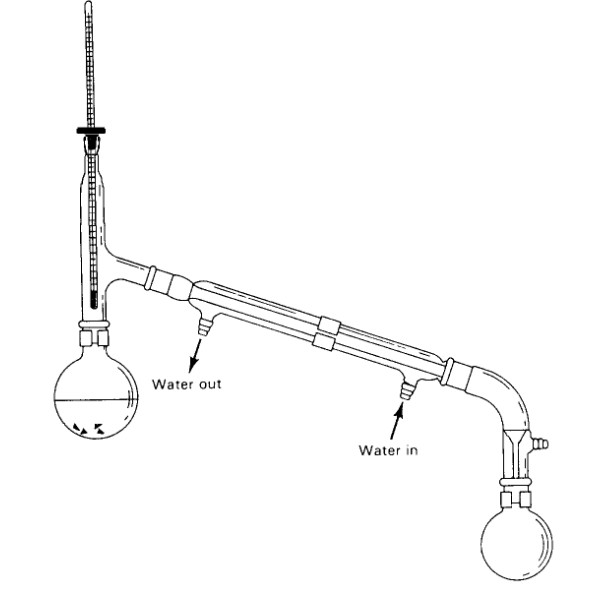

Simple Distillation vs Molecular Distillation

Distillation types include simple distillation, where various unstable distillation parts are collected upon delivery. In this type, the destructive distillate is usually heated so that the material decomposes into mixtures for accumulation.

Simple Distillation

Simple distillation can be used when the breakpoints of two fluids are not very similar or to isolate liquids from solids or non-volatile parts. In a simple distillation process, the mixture is heated to change the unpredictable part of the liquid into steam. The steam rises and goes to the capacitor. For the most part, the condenser is cooled to drive accumulated steam accumulation.

Molecular Distillation

Molecular distillation is used industrially to clean oils. It enriches borage oil in the erosion of linolenic to recover tocopherol from the deodorant product of soybean oil. Molecular smears were used in a combination of large polymers as a response element, punctuated by polymerization. That means, the retracting gives a response by hydrolysis, yet water can be expelled by molecular distillation.

Some Points You Need To Pay Attention To When Using Molecular Distillation

There are several precautions to take when using molecular distillation. Here are the precautions:

1. Boiling

Check on the boiling point of the compounds you intend to separate. The whole concept of molecular distillation relies on temperature. In some cases, too high temperate can denature the compounds. Always take the precaution when carrying out the distillation process.

2. The Purity of the Compounds

Check on the purity of the compounds required. For high purity levels, invest in a molecular distillation apparatus that can achieve a high level of purity in the process.

3. Pressure Regulation

You have to reduce the pressure and achieve molecular distillation. The apparatus should have a precise mechanism of lowering the pressure.

4. Temperature regulation

You need to regulate the temperatures at different boiling points. Ensure the apparatus you are using has some mechanism of controlling the temperature for effective molecular distillation.

Molecular Distillation vs. Fractional Distillation

There is a difference between molecular distillation vs. fractional distillation. Molecular distillation involves the reduction of pressure as a way of lowering the boiling point. It is different from the concept of fractional distillation, which involves boiling the mixture until it reaches its boiling points. A mixture separated using fractional distillation involves ingredients that boil at different temperatures. It is a method that is applied to separate crude oil into its constituent petroleum products.

1. Stability of the Molecules

Fractional distillation is applied to separate stable components. It is different from molecular distillation, which involves separation of compounds which are unstable at high temperatures. For example, the separation of natural oils requires the application of molecular distillation. The distillation process involves lowering the pressure of the boiling liquids as a way of reducing their boiling points. The compounds separated through molecular distillation achieve high purity levels.

2. Applications

Molecular distillation is applied to separate unstable molecules such as CBD oils. On the other hand, fractional distillation is applied to separate petroleum oil products. The use of molecular distillation is required where the products to be separated have low boiling points.

3. Pressure Control

There is a need for pressure control in molecular distillation. It is a different case when applying fractional distillation. You will not require the regulation of pressure when separating compounds based on fractional distillation. In most cases, the ingredients are stable at the temperatures. Molecular distillation requires special equipment that allows control of the pressure.

4. Temperature Control

Both the process requires temperature control. The temperatures at which the liquids are separated in molecular distillation are lower. Fractional distillation involves high temperatures. Fractional distillation relies on the principle where the mixture is separated based on the different boiling points of the mixture.

Difference Between Short Path Distillation and Molecular Distillation Equipment

Short Path Distillation

Short-path or short-range distillation, alluding to a short distance, using a micro evaporator dissipation surface that summarizes the cumulative surface distance of less than 300 mm, can be called distillation of a very short range.

The scraper is divided into a short distillation device of the design structure, and a short-path centrifugal distillation method. At the moment, there are some manufacturers of condenser evaporator construction for incandescent films and an excellent distillation site short.

Besides, the virtue of distillates also depends on the thickness of the film. The positive controlled pressure on the distillation and the supply of the hot surface of the evaporator will provide a uniform film throughout the distillation process. That will reduce the process factors of the expected changes that are caused solely by temperature changes caused By the constant operator.

As of now, the most mature innovation is the brief abrasive distillation process, which is designed using a vertical drum that fades with external heating.

The condenser and mop focus on the transition between the distillation and recycling sectors of condensate. The distillation process uses materials that are included from the highest point in the evaporator. The rotating liquid feed dispenser will move continuously without stopping on the hot surface, at which time the detergent film will keep the layer arranged in a layer very thin. The liquid membrane will look like a shell; it will progress to With downward curves.

In this process, the light part of the heating surface is cut, after very short cycles and with almost no effect on the density of the liquid to the internal condenser, and the condenser tubes along a stream through the evaporator in the base of the drainpipe; Through the side of the liquid in the pipe material.

Molecular distillation equipment is exactly gradual to clarify the principle, which is not very different from that of conventional distillation, depends on the policy of separation of the breakpoint difference. The process is carried out when the liquid mixture under specific pressure conditions. It then flows along with the heating plate and light and large particles of liquid to escape as gas due to the diversity of the light particles that are released.

Therefore, the different surface molecules that move after escape multiple distances; if a condensed plate is appropriately prepared, light is a full discharge plate with substantial molecular access. The large particles reach the accumulation plate along with the evacuated mixture. These substances achieve the purpose of separation.