This system was invented by Lyman C. Craig and was first used by the Swiss company in pilot plants for chemical operations. A rotary evaporator also is known as Rotavap, is an apparatus used in chemical laboratories for efficient removal of solvents from the samples at low pressure by evaporation. The rotatory evaporator is designed to work under a vacuum, to lower the boiling point of molecular compounds as well as heating the sample. It is also used in molecular cooking to prepare extracts and distillates.

A rotatory evaporator is used in many fields to concentrate and separate substances in a mixture, the fields include chemical laboratories, industrial fields, food processing, among others. When working, the round-bottomed flask where evaporation takes place is kept rotating at a constant speed to increase the rate of evaporation by increasing the evaporation area.

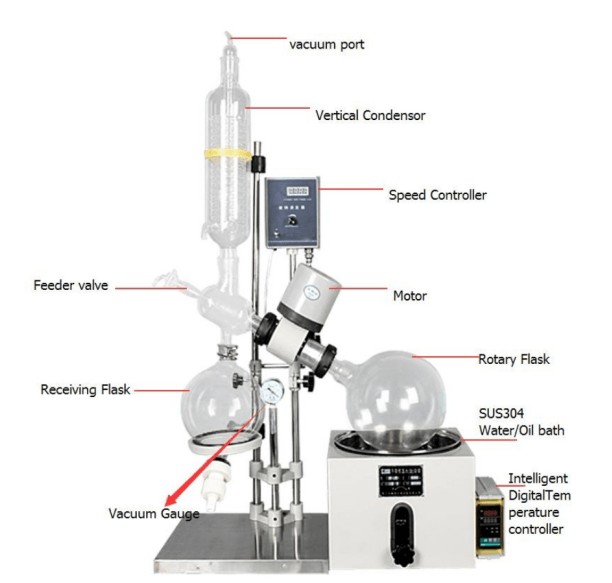

The Main Parts of A Rotary Evaporator and Functions.

1. Rotary motor.

A rotary evaporator consists of an electric-powered motor that plays an important role by rotating the evaporation flask at a continuous and constant speed. This results in an increased surface area for evaporation as well as even mixing, heating hence a stable and even evaporation.

2. Vacuum source.

This is the system responsible for creating a vacuum within the airtight set-up, thereby reducing the pressure within the system. The vacuum source can be simply a water aspirator consisting of a water immersed trap, or a complex mechanical vacuum pump consisting of a refrigerated trap.

3. Glass tube.

The glass tube has two functions, the first is to protect and support the sample during rotation while the second is to help in the creation of a vacuum.

4. Heating bath.

The mainly used heating bath is a hot water bath. The function of the heating pot is to heat the sample and help in temperature regulation.

5. Condenser.

It is mainly found in a double snake shape and the function is to condensate the evaporated sample as well as enhance convenient sample collection.

6 Receiving flask.

The function of the collecting flask is to receive the distilled sample.

The glassware used in the condenser and the vapor stream is dependent on the evaporation goals and the mixture propensities, it can be simple or complex. Modern rotary evaporators also consist of a digitalized system with digital display for temperature and rotation speed, vapor temperature sensor, and digital vacuum control.

Types of Rotary Evaporators.

1. 2L rotary evaporator.

This is a 2L series rotary evaporator that consists of vertical glassware, modular heating bath, and automatic temperature control. It is designed to allow quick heating due to the optimized bath volume. The condenser unit also consists of specially designed glass tubes to increase the surface area for maximum condensation. This type of rotary evaporator also consists of safety features like fuse protection, dry-run protection, and water bath over-heating control.

2. 5L rotary evaporator.

This is a common chemistry laboratory equipment used for the continuous distillation of volatile solvents in large numbers under low pressure. In this apparatus, the condenser is used to connect the distillation flask and the receiving flask which collects the evaporated solvents. The 5L rotary evaporator is applied in chemical engineering, medicine industries for drying, solvent recovery, concentration, separation, and purification especially to substances that easily decompose at high temperatures.

3. 10L rotary evaporator.

This is a type of evaporator with a 10L capacity rotary bottle and a 5L capacity receiving bottle. The rotary bottle of this evaporator is equipped with a double condenser thus making it have a high recovery rate and also to have a higher condensation effect. It works using the motor to rotate the rotary flask at a constant speed, this makes the substances to occupy a large space of a thin film. Then the water bath with a constant temperature is used to heat the rotary flask leading to a high evaporation rate under the vacuum condition.

The 10L rotary evaporator has a spacious capacity that would hold sample sizes that are large enough and beyond the limit of other ordinary evaporators. It also has a motorized water bath lifting system, this system allows you to monitor the controls. It minimizes errors that may occur during application thereby ensuring a smooth operation.

Digitalized speed and a temperature display, this feature in the 10L rotary evaporator allow for straight forward and easy visual operation. With these features present any chance of misinterpretation which may arise is prevented. The 10L rotary evaporator has a proportional integral differential temperature controller that ensures the accurate temperature is maintained. Good mobility. This apparatus possesses a stronger swivel caster which is used for turning it around.

4. 50L rotary evaporator.

The 50L rotatory evaporator is very spacious due to its high capacity. The evaporator kit is convenient with a 50-liter evaporation flask and a 20-liter collection flask. This makes the device effective and speedy in carrying out operations. The rotatory vacuum evaporator in the 50L rotavap gives heat to the bubble flask at a constant rate. This ensures it rotates at a constant speed hence the fluid forms a large film on the sides of the jar.

The 50L rotatory evaporator has a glass condenser that cools the soluble steam. When cooled it is recovered in the accumulator bottle. This is a great improvement to evaporation productivity. The 50L rotatory evaporator is designed to be suitable for the concentration and purification of biological samples that can denature at very high temperatures. This makes the apparatus versatile. Flexible evaporators combined with polyethylene are used during sealing. This ensures there is a guaranteed high vacuum and a rotational speed that can be adjusted.

Applications of a Rotary Evaporator.

1. Applications in the Laboratories.

The device is applicable in the medical and biological fields. Being able to handle heat-sensitive procedures, can be used with biological samples which are denatured by extreme temperatures.

The device can also be used to carry out molecular cooking together with molecular gastronomy. For molecular cooking, it is an innovation established to carry out cooking activities.

Another important application for the rotatory evaporator is the removal of solvent samples. This procedure works through the evaporation process. This happens when the rotatory evaporator is used in molecular cooking with an aim of extraction together with distillation.

2. Drying powders.

Rotavaps can be used to dry powders. For this to happen they have to be attached to a test tube adapter. This approach does not involve complicated procedures hence a simple and effective method.

3. Mixing reactants.

The rotatory evaporator contains a heated water bath. In this chamber, the user pours the reactants which are rotated vigorously to enable mixing.

4. Flavor extractions.

The rotavap can be used in industries to extract flavors. The tool is again very reliable since it does not result in loss of flavor during extraction. These flavors are used in preparations for drinks and foods.

5. Sample preparations.

There are scenarios where the samples required should be highly concentrated. The rotatory evaporator comes to the rescue. It extracts excess solvent to leave behind a high concentration of solute. Thus in this way the device serves its purpose as needed.

6. Solvent removal, separation, and Recycling.

In procedures involving removing, recycling and separating solvents the rotatory evaporator removes the excess solvent from a solution. In this method, it manages to remove the solvent from the solution and also recycles it.

7. Trapping Hazardous waste liquids.

The rotatory evaporator traps hazardous fluids from a solution. Being able to perform this procedure, it has many applications in an industrial setting which employs large volumes of fluids and chemicals. It can also be employed in government parastatals so as to save the surroundings.

8. Educational and informational.

The 100L rotatory evaporator has been under various occasions used for educational purposes and informational inquiries. Examples of these are information on chemicals and environmental purposes.

Due to these, the 100L rotatory evaporator can be found in schools, medical laboratories as well as museums and also other facilities dealing with heavy machinery.

>More Educational Rotary Evaporator: Educational Rotary Evaporator

9. Pharmaceutical industries.

The rotatory evaporator is mainly used in the pharmaceutical industries to carry most procedures.

The device can be used to mix ingredients that would be rendered almost impossible to mix using ordinary kinds of mixing apparatus. Due to this, the apparatus proves efficient in enhancing the efficacy of reactions.

10. Collecting the final outcome.

Since these devices are designed to have a condenser and a condensate collecting flask, it becomes easier to collect the end products in the laboratories. Carrying out these activities the user is comfortable and has convenience in mind.

Conclusion.

A rotary evaporator is an important apparatus for most analytical, extraction, processing, and production procedures. The different parts are designed to ensure efficiency in carrying out these procedures.