The double-layer glass reactor is a vessel in which chemical reactions are carried out. The double-layer reactor has two insulation layers which help in controlling the condition under which the reaction is carried out. For example, experts need glass reactors to control the temperature and pressure under which the chemical reaction is carried out.

The use of a double layer reactor allows for easy control of the reaction parameters. The first insulation layer can have a water layer that acts as insulation, while the second layer can have a vacuum unit that offers extra insulation.

Features of Double-Layer Glass Reactor

The double-layer glass reactor comes with several features. There are several designs of double-layer reactors. The type of reactor you are using will determine the features you can access.

Here are features available in the double-layer reactor:

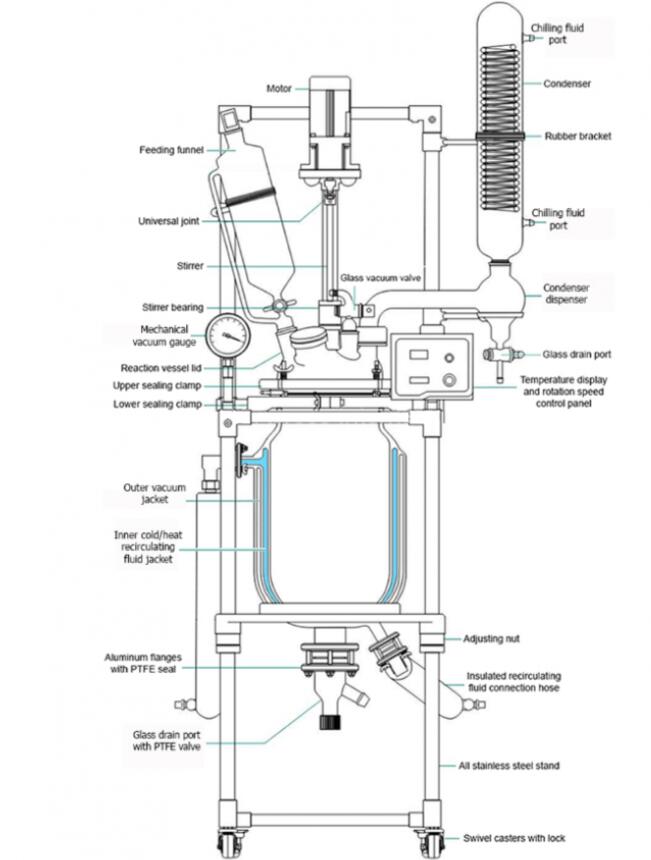

1. Vacuum jacket

There are two layers of protection in the double-layer reactor. The first jacket consists of a vacuum jacket. In the vacuum jacket, there is control of temperature and pressure. The chemical reactions are controlled due to the creation of a virtual vacuum.

2. Fluid jacket

Different types of fluids can be used in the process. The experts can apply fluids with certain chemical properties as a way of creating the right environment under which the chemical reactions will be carried out.

3. Reaction vessel

It is the vessel in which the chemical reactions occur. Different substances can be mixed in the reaction vessel to come up with the desired results. The reaction vessel contributes to the production of different desired outcomes.

The Specifications of WKIE Lab Double Layer Glass Reactor

| Model | S212-05 | S212-10 | S212-20 | S212-50 | S212-100 | S212-200 |

| Reaction Volume(L) | 5L | 10L | 20L | 50L | 100L | 200L |

| Jacket Volume(L) | 2L | 5L | 8L | 12L | 18L | 25L |

| Reactor Material | High quality borosilicate 3.3 glass | High quality borosilicate 3.4 glass | High quality borosilicate 3.5 glass | High quality borosilicate 3.6 glass | High quality borosilicate 3.7 glass | High quality borosilicate 3.8 glass |

| Support Frame Material | Stainless steel 304 and coated aluminum | Stainless steel 304 and coated aluminum | Stainless steel 304 and coated aluminum | Stainless steel 304 and coated aluminum | Stainless steel 304 and coated aluminum | Stainless steel 304 and coated aluminum |

| Neck No. On Lid | 5 | 6 | 6 | 6 | 6 | 6 |

| Rated. torque(N.cm) | 140 | 177 | 177 | 177 | 285 | 550 |

| Motor power(W) | 90 | 120 | 120 | 120 | 200 | 370 |

| Rotating speed(rpm) | 0 ~ 600 (customizable) | 0 ~ 600 (customizable) | 0 ~ 600 (customizable) | 0 ~ 600 (customizable) | 0 ~ 600 (customizable) | 0 ~ 600 (customizable) |

| Power supply | 220V or 110V / 50-60HZ | 220V or 110V / 50-60HZ | 220V or 110V / 50-60HZ | 220V or 110V / 50-60HZ | 220V or 110V / 50-60HZ | 220V or 110V / 50-60HZ |

| Discharge | PTFE (Teflon) bottom discharge valve with no deadspace | PTFE (Teflon) bottom discharge valve with no deadspace | PTFE (Teflon) bottom discharge valve with no deadspace | PTFE (Teflon) bottom discharge valve with no deadspace | PTFE (Teflon) bottom discharge valve with no deadspace | PTFE (Teflon) bottom discharge valve with no deadspace |

| Pressure Range | Full vacuum to atmosphere | Full vacuum to atmosphere | Full vacuum to atmosphere | Full vacuum to atmosphere | Full vacuum to atmosphere | Full vacuum to atmosphere |

| Max jacket pressure | 0.5 bar | 0.5 bar | 0.5 bar | 0.5 bar | 0.5 bar | 0.5 bar |

How Does Double-Layer Jacketed Glass Reactor Work?

A double-layer reactor has two layers of insulation. The two layers help in controlling the conditions under which different processes are carried out in the reaction vessel.

The Applications of Double-Layer Glass Reactors

The applications of a double-layer glass reactor vary. You can find the reactor used in the chemical process or in the laboratory to separate substances. In a field such as CBD oil processing, the double walls reactor has been applied widely. There is a need to control the condition under which the chemical processes occur. The application of the double-layer glass reactors makes it possible to control the chemical reactions.

The double-layer chemical reactors come in several designs and shapes. They also vary based on the size. You need to buy one which can accommodate your given applications. For example, people who are engaged in big chemical processes tend to require big units. The manufacturers of the reactors avail them in different sizes. This is to meet the needs of many people in society.

The Applications of Double-Layer Glass Reactor in Laboratory

In laboratories, the double layer glass reactors are applied to accomplish several processes.

Here are some of the uses of the double-layer glass reactors in laboratories:

1. Extraction of oils

Several extraction processes require regulation of temperatures. The double-layer reactors play a significant role in the control of temperatures during the extraction of oils from natural sources. For example, the extraction of CBD from cannabis can be achieved through the application of the double-layer glass reactors. The glass reactors come in different shapes and designs. You need to buy one for each given purpose.

2. Winterization process

In the laboratory process, which requires winterization, the double layer reactors are required. Not all reactors can work well for the winterization process. You need to check on the design of a given reactor before you can proceed to buy it for the winterization process.

3. Distillation process

There are distillation processes such as molecular distillation, which require control of temperature and pressure. The application of double-layer reactors makes it easy to control the parameters required to achieve the given conditions necessary for the production of different substances.

The Applications of Double-Layer Jacketed Glass Reactor in Chemistry

In chemistry, double-layer glass reactors are applied in several processes. The reactor plays a great role in controlling conditions under which different chemical processes occur. When experts need to control temperature and pressure, they rely on the reactors to realize the best processes.

Here is one of the applications of double-glass reactors in chemistry:

Ethanol extraction

The process of ethanol extraction from botanical material relies on controlling temperatures. The double-layer glass reactor plays a big role in such cases. The experts apply double layer reactors of different sizes to achieve the extraction process. In large scale processes, big double-layer glass reactors can be applied to realize the best results.

Conclusion

In fact, the choice of the double-layer glass reactor depends on several factors. The experts will take into consideration several factors before they can proceed to apply a given double-layer reactor.

With the right choice of the reactors, it becomes easy to control the processes. In some cases, the right selection of the reactor can contribute towards improving the quality of results in the chemical processes.