10L rotary evaporator can meet almost all of your needs, although there are many kinds of rotary evaporators on the market. And this one, as its name states, has the capacity of 10 liters.

Thanks to this awesome capacity, it is capable of handling ingredients that are slightly larger than those of your ordinary equipment.

We shall discuss what it has on offer in details hereunder.

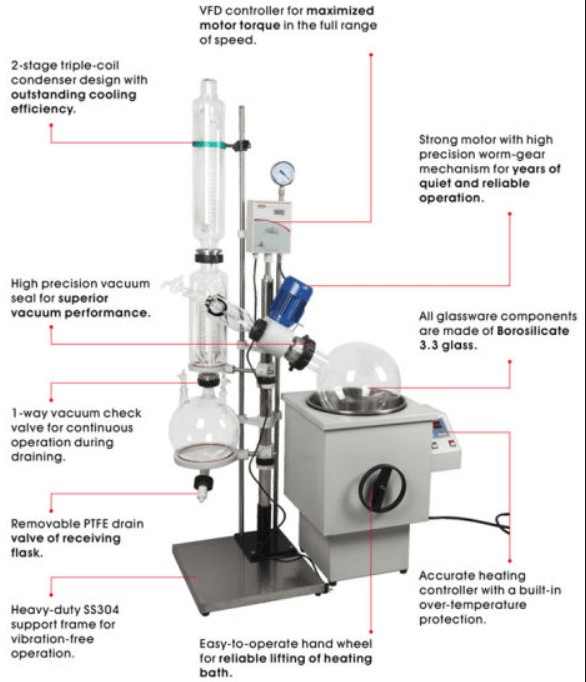

The Structures of 10L Rotary Evaporator

Rotary Motor

A rotary motor stands tall among all the parts and features it contains. The motor draws its power from electricity and operates some constant speed. Due to these two issues, the motor manages to exude the power required for most operations.

Evaporation Glass Tube

Next comes the evaporation glass tube. It is in this glass tube that the samples that are worked on are poured. Another camber aids with the extraction of the solvent and its final storage.

Vacuum Device

Rotary evaporators work by lowering the pressure inside the chamber. A vacuum device plays this role. It creates a low pressure principally by sucking out all air in the chamber. This in return makes your solutions to hit the boiling points at lower temperatures.

Liquid Heating Bath

A liquid heating bath is the core of the evaporator. It is in the liquid heating bath that you heat the samples to extract the solvents. The bath also gives you the power to control the temperature and create a conducive environment for solvent extraction.

Condenser Pipe

The condenser pipe connects the liquid heating bath to the evaporation glass tune. It acts as a conduit for the transmission of the heated liquids from the former to the latter chamber. In doing so, it also cools and condenses the samples.

Receiving Flask

Lastly comes the receiving flask. This is the final stage of the evaporator in that it is the one that collects the final products. Its purpose is basically to receive the distilled samples.

The Specifications of 10L WKIE Lab Rotary Evaporators

| Model | R-1010 | R-1020 | R-1050 | RE-1002 | RE-2002 | RE-3002 | RE-5002 |

| Rotation Flask | 10L | 20L | 50L | 10L | 20L | 30L | 50L |

| Bath Lift | Motor Lift | Motor Lift | Motor Lift | Hand Lift | Hand Lift | Hand Lift | Hand Lift |

| Condenser | Glassware: Vertical with dual-spiral glass tubing | Glassware: Vertical with dual-spiral glass tubing | Glassware: Vertical with dual-spiral glass tubing | Glassware: Vertical with dual-spiral glass tubing | Glassware: Vertical with dual-spiral glass tubing | Glassware: Vertical with dual-spiral glass tubing | Glassware: Vertical with dual-spiral glass tubing |

| Flask Rotation Speed | 0-120rpm | 0-120rpm | 0-120rpm | 0-110rpm | 0-110rpm | 0-110rpm | 0-110rpm |

| Motor Power | 250W | 250W | 250W | 180W | 180W | 250W | 250W |

| Receiving Flask | 5L | 10L | 20L | 5L | 10L | 20L | 20L |

| Vacuum Degree(Ultimate Pressure) | 20mbar | 20mbar | 20mbar | 20mbar | 20mbar | 20mbar | 20mbar |

| Heating Power(customizable) | 4KW | 4KW | 6KW | 3KW | 5KW | 8KW | 8KW |

| Temp. Control | PID from main heater, ON/OFF Control | PID from main heater, ON/OFF Control | PID from main heater, ON/OFF Control | PID from main heater, ON/OFF Control | PID from main heater, ON/OFF Control | PID from main heater, ON/OFF Control | PID from main heater, ON/OFF Control |

| Safety | Over-temp and fuse protections | Over-temp and fuse protections | Over-temp and fuse protections | Over-temp and fuse protections | Over-temp and fuse protections | Over-temp and fuse protections | Over-temp and fuse protections |

| Glass Material | High borosilicate glass 3.3 | High borosilicate glass 3.3 | High borosilicate glass 3.3 | High borosilicate glass 3.3 | High borosilicate glass 3.3 | High borosilicate glass 3.3 | High borosilicate glass 3.3 |

| Power Source | 220V 1ph, 50HZ(Customized: 110V) | 220V 1ph, 50HZ(Customized: 110V) | 220V 1ph, 50HZ(Customized: 110V) | 220V 1ph, 50HZ(Customized: 110V) | 220V 1ph, 50HZ(Customized: 110V) | 220V 1ph, 50HZ(Customized: 110V) | 220V 1ph, 50HZ(Customized: 110V) |

The Features of 10-Liter Rotovap

1. Spacious Capacity

Topping the list of the many features of this evaporator is the spacious capacity. This comes to 10 liters. Thanks to this awesome capacity, the evaporator is capable of handling sample sizes that are sufficiently large and beyond the scope of many ordinary evaporators.

2. Water Bath Lifting

A motorized water bath lifting also exists as part of the makeup of this wonderful piece of equipment. This mechanism allows you to accrue the benefit controls. It minimizes the errors which may often arise in the course of use and applications. Also, it guarantees the smoothest operations imaginable.

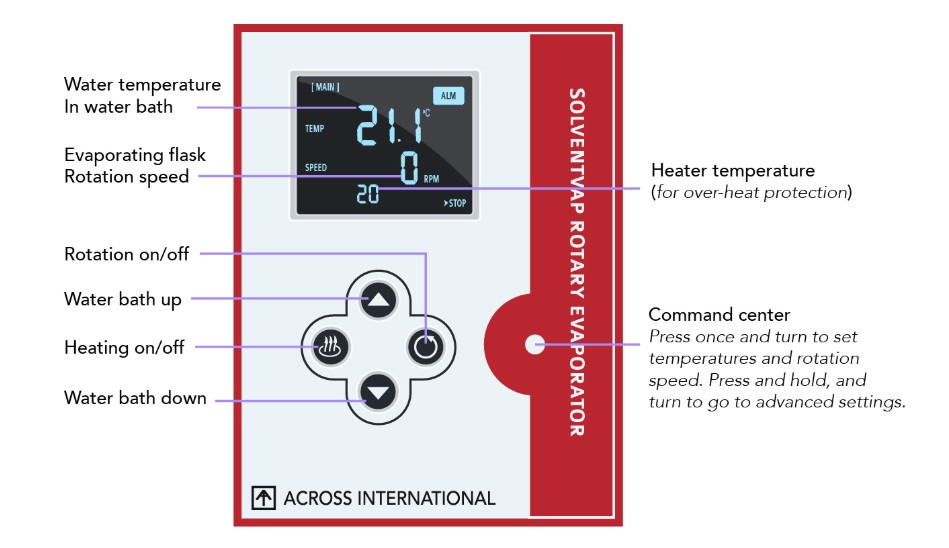

3. Digital Speed and Temperature Display

As you make use of this apparatus, you will enjoy the pleasure of utmost preciseness. This is made possible by the digital temperature and speed displays. They allow for straightforward and easy visual operations. This gain goes a long way in preventing any ambiguities which are ordinarily bound to arise while in use.

4. PID Temperature Controller

Courtesy of its proportional integral differential temperature controller, this appliance sees to it that you maintain accurate controls of your temperature. In doing so, it hence guarantees that you do a good job on the whole of manning the progress of your samples. All you have to do is keep a watchful eye on the evaporation process.

5. Awesome Mobility

The 10-liter rotary evaporator also boasts of awesome mobility. That is because it possesses the stronger swivel casters which play the role of turning it out and about. With this arrangement in mind, the evaporator may also travel smoothly on the most uneven floors. Moreover, the casters also secure firmly to prevent any slippage.

6. Long-term Operations

By all accounts, the 10-liter rotary evaporators manage long-term operations. This stems from its possessions of the Viton gaskets and the solvent-resistant Polytetrafluoroethylene (PTFE) material makeup. These two are ordinarily harder to break down and will hence guarantee smooth operations at all times of use.

7. Quiet Operations

Other than long-term operations, the evaporators also manage quieter operations. Their specialized motors are extremely compact. They are hence less likely to emit the heavy sounds which other kinds of apparatus do emit. At the same time, they are also vibration-free and will hardly imperil your aural faculties.

8. Uniform Temperature Output

One distinctive feature of this equipment is the uniform temperature output it exudes. Indeed, throughout its operations, it sees to it that the temperature produced is more or less constant. This one gives way for better outcomes and long-term reliability. It also saves you plenty of utility expenses.

9. Utmost Safety

In closing, the evaporator also manages the utmost safety. This safety is mainly brought about by the water bath cover. It shields the evaporating flask and the materials that are contained therein from all forms of external interferences. At the same time, it also spares you of any chemical burns and other likely issues.

The Applications of 10L Rotary Evaporator

1. Extraction of Solvents

The number one role that is played by these evaporators is the extraction of solvents. This equipment indeed does eliminate solvents from the solutions. Unlike other techniques, they do so in a faster, safer, and more convenient manner. What’s more? The solvents that are extracted are in the crystalline forms.

>> Can Rotary Evaporators Remove Water?

2. Purification of Solutions

You may also employ this evaporator to purify your solutions. Unlike the process of distillation, this one purifies the solutions but without the undesirable side effects of higher utility bills. That is because it lowers the boiling points of the solutions. In doing so, it reduces the quantity of heat you have to expend.

3. Heating Samples

Just want to heat samples? The 10-liter evaporator is yet again yours for the taking. As we have explained before, this equipment first and foremost lowers the temperatures of samples. This makes the samples attain boiling points sooner. It also negates the input of too much heat energy.

4. Mixing Solutions

Though primarily meant to extract solvents, these evaporators may also be used to mix solutions and samples in the lab. If you opt to devote yours to this end, you have to be sure that they do not react adversely. The least you would want to happen to you is an explosive and potentially deadly reaction.

5. Separating Vapors

Fractional distillation has been widely used to separate colors and vapors. However, it does have some serious drawbacks. Chief among these are the high energy costs and the prohibitive startup capital. The 10-liter rotary evaporators have the added advantage of reduced operational expenses.

6. Food Industry

Lastly, this piece of equipment is widely employed in the food industry. Here, it plays the role of processing, preservation, and handling of all kinds of foods. It is safer and more diligent to make use of as opposed to its many counterparts. As a bonus, it also works wonders in mixing beverages.