A 50L rotary evaporator is suitable for chemical labs to remove solvents from samples efficiently and smoothly by evaporation. The rotational evaporation process is regularly used to separate waters with low boiling concentration, such as n-hexane or ethyl acetate, from active mixtures at room temperature and pressure.

However, the precise application also allows the removal of a soluble substance from a sample containing a fluid compound if there are little evaporation and sufficient boiling contrast centered on the selected temperature and pressure reduction.

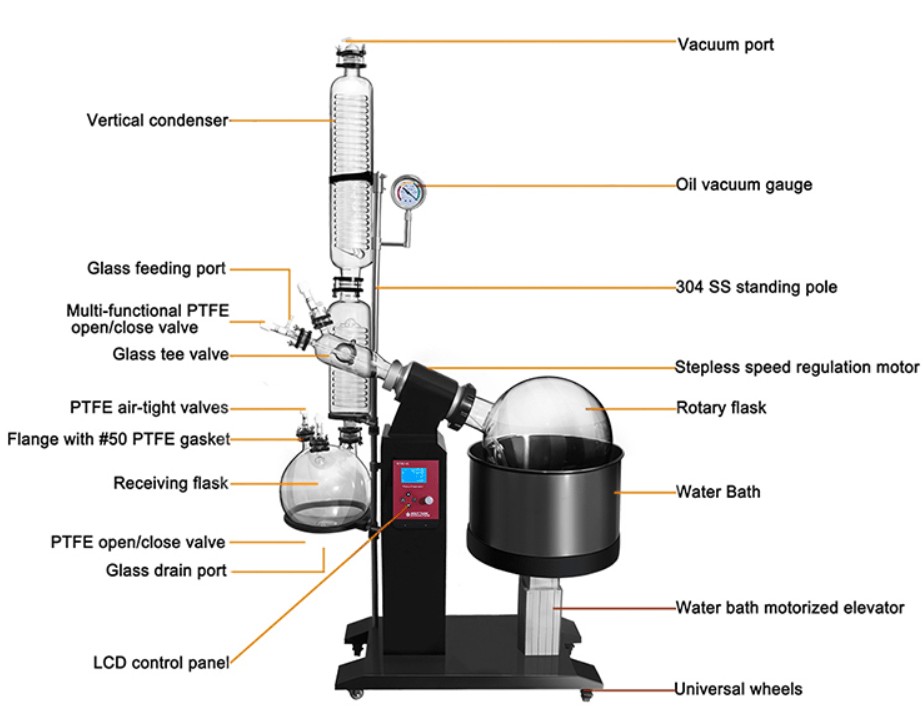

The Structure of 50L Rotary Evaporator-50 Liter Rotovap

The 50L rotary evaporator is a device used in chemical laboratories to remove solvents from samples efficiently and smoothly by evaporation. Thus, the rotary evaporation process is often used to separate low boiling solvents, such as n-hexane or ethyl acetate, from active mixtures at room temperature and pressure.

Current 50L rotary evaporators can also be designed for production and production using equipped high capacity flasks.

The 50L rotary evaporator adopts the evaporation zone by expanding the flask at low pressure, to make the solution in the diffuse jar evaporate. They are the essential and ideal equipment for the chemical business, the pharmaceutical industry, the fundamentals of higher education, and the logical research laboratories.

Besides, rotovap has an engine specifically with gears and worms, which provides constant rotation at speeds ranging from 10 to 180 pm. When a vial containing a soluble substance is rotated, it continuously transports a small layer of liquid over the entire internal surface. This provides a huge surface area for evaporation caused by the gentle heating of the water bath.

Moreover, the circulation system is equipped with a special seal, allowing the device to be placed under vacuum, which adequately reduces the boiling of solvents and eliminates the vapor phase, making the process more efficient. Further, each unit an easy-to-use vacuum release and a continuous feed system, which allows you to drag the melt continuously into a rotating flask without waiting for the process to stop.

The Specifications of 50L WKIE Lab Rotary Evaporators

| Model | R-1010 | R-1020 | R-1050 | RE-1002 | RE-2002 | RE-3002 | RE-5002 |

| Rotation Flask | 10L | 20L | 50L | 10L | 20L | 30L | 50L |

| Bath Lift | Motor Lift | Motor Lift | Motor Lift | Hand Lift | Hand Lift | Hand Lift | Hand Lift |

| Condenser | Glassware: Vertical with dual-spiral glass tubing | Glassware: Vertical with dual-spiral glass tubing | Glassware: Vertical with dual-spiral glass tubing | Glassware: Vertical with dual-spiral glass tubing | Glassware: Vertical with dual-spiral glass tubing | Glassware: Vertical with dual-spiral glass tubing | Glassware: Vertical with dual-spiral glass tubing |

| Flask Rotation Speed | 0-120rpm | 0-121rpm | 0-122rpm | 0-123rpm | 0-124rpm | 0-125rpm | 0-126rpm |

| Motor Power | 250W | 250W | 250W | 180W | 180W | 250W | 250W |

| Receiving Flask | 5L | 10L | 20L | 5L | 10L | 20L | 20L |

| Vacuum Degree(Ultimate Pressure) | 20mbar | 20mbar | 20mbar | 20mbar | 20mbar | 20mbar | 20mbar |

| Heating Power(customizable) | 4KW | 4KW | 6KW | 3KW | 5KW | 8KW | 8KW |

| Temp. Control | PID from main heater, ON/OFF Control | PID from main heater, ON/OFF Control | PID from main heater, ON/OFF Control | PID from main heater, ON/OFF Control | PID from main heater, ON/OFF Control | PID from main heater, ON/OFF Control | PID from main heater, ON/OFF Control |

| Safety | Over-temp and fuse protections | Over-temp and fuse protections | Over-temp and fuse protections | Over-temp and fuse protections | Over-temp and fuse protections | Over-temp and fuse protections | Over-temp and fuse protections |

| Glass Material | High borosilicate glass 3.3 | High borosilicate glass 3.3 | High borosilicate glass 3.3 | High borosilicate glass 3.3 | High borosilicate glass 3.3 | High borosilicate glass 3.3 | High borosilicate glass 3.3 |

| Power Source | 220V 1ph, 50HZ(Customized: 110V) | 220V 1ph, 50HZ(Customized: 110V) | 220V 1ph, 50HZ(Customized: 110V) | 220V 1ph, 50HZ(Customized: 110V) | 220V 1ph, 50HZ(Customized: 110V) | 220V 1ph, 50HZ(Customized: 110V) | 220V 1ph, 50HZ(Customized: 110V) |

Applications

50L rotary evaporator is suitable to investigate the evaporation, distillation, or separation of chemicals. It usually works with a vacuum siphon that rotates with water and recycles the chiller in a comprehensive system to meet production and experimentation conditions.

Features of 50L Rotary Evaporator

- The 50L rotary evaporator kit is convenient with a 50-liter evaporation flask and a 20-liter collection flask.

- Rotary vacuum evaporator under vacuum conditions, give constant heat to the bubble flask, it will rotate at a constant speed, and the liquid can form a large area film on the wall of the jar.

- 50L rotary evaporator parts: soluble steam is cooled by a high-efficiency glass condenser and recovered in the accumulator bottle, which significantly improves evaporation productivity.

- The 50L rotary evaporator is particularly suitable for the concentration and purification of biological elements that can easily collapse and deform at high temperatures.

- Polyethylene and flexible evaporators are used in the sealing process and guarantee a high vacuum and an adjustable rotation speed.

The Advantages of 50L Rotary Evaporator

- Patented Teflon double seal innovation and PV flexibility ensure the level of negative pressure.

- The automatic switching valve makes continuous accumulation impossible without affecting the vacuum and without stopping distillation.

- Teflon discharge valve is consumable and does not contaminate.

- The water jacket protects the operator from hot liquid burns.

- Lift a water bath with a motor for precise control.

- The PID temperature control guarantees precise temperature control.

- The optional stainless steel flask holder with silicone pads is designed for safer loading and unloading of the flask.

Precautions During Loading of The 50L Rotovap

- The 50L rotary evaporator must be returned in a shock-resistant padded case, marked with an “inclined” outside the case and carefully handled optical or electrical instruments, correctly placed, strictly prohibited from intense pressures, and accompanied if necessary in the equipment.

- The 50L rotary evaporator in the engine transmission should avoid volatility and vibration, and should generally be placed in front of the soft palate, or by people hanging from the legs or backpack mounted on the base of the cabinet.

- The steam must be maintained vertically so that the tool can keep the state of the siphon vertically and must not be transported horizontally on the shoulder to avoid damaging the device or the column system. Turn the system.

Precautions When Unloading, Filling, and Closing The 50L Rotary Evaporator

- After turning on the 50L rotary evaporator find out the comparison positions for all components. When removing the device, hold the stand with one hand and the base with the other side or gradually remove it with both sides. The use of a horizontal axis by hand is strictly prohibited.

- Fix the tripod before removing the device. Put it on the tripod after removing it and secure it with the center screw.

- The 50L rotary evaporator should not be left before packing.

- When filling the 50L rotovap the brake screw must be fixed or released according to the type of device.

- Check the stability of the tools and the natural result to avoid damage to the device during transport.

- When the fund has an abnormal distribution, we must find out the cause before the coverage. It is strictly forbidden to press hardcovers and covers.