The applications of rotary evaporators are widespread from factories to laboratories, and today they are even used for cooking purposes in kitchens.

The basic principles of rotary evaporators are based on lowered pressure distillation, evaporation flask, snakelike condenser pipe, receiving flask, water bath, and motor. These make up the main components of the rotary evaporator.

The Basic Applications of A Rotary Evaporator

Purify and Separate A Reaction Product

The rotary evaporator is primarily used for the continuous distillation of different volatile solvents that are placed under lowered pressure conditions. More specifically, the concentration associated with the extract, along with the distillation of a receiving liquid linked with chromatographic separation, is able to purify and separate a reaction product.

Educational Use

The applications of the rotary evaporator are mainly focused on scientific research along with the production processes of chemical, biological, pharmaceutical products, along with other industries. The functions of a rotary evaporator have to do with evaporation, crystallization, concentration, drying, solvent recovery, and separation.

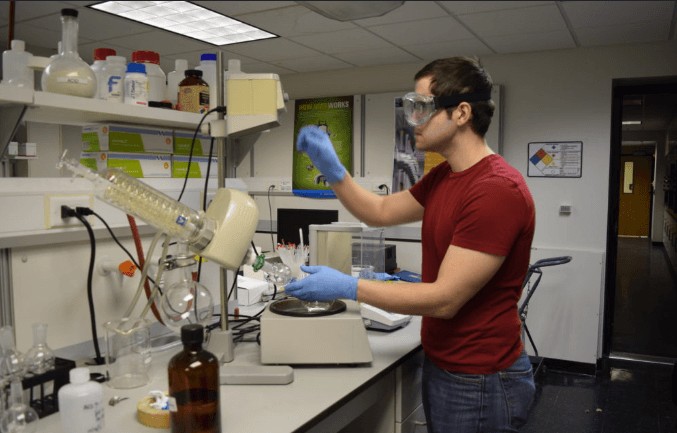

Educational rotary evaporators are also widely used for teaching experiments in laboratories. During these experiments, when an evaporation bottle is used on a table, it does not roll or break easily, which helps to reduce the expenses relating to school experiments.

Applications of Rotary Evaporator in Industry.

The main application industries linked with rotary evaporators are biological, chemical engineering, and medical products relating to the production and different types of scientific research. Crystallization, evaporation, separation, solvent recovery processes, and drying are all necessary for all the industries that handle and process reaction solvents.

Laboratories are other areas where industrial rotary evaporators play an important role. During experimental processes, the evaporating flask is displayed on top of a desk, where it won’t roll or break.

In Molecular Cooking Industry

In more recent years, the rotary evaporator applications are now used within the cooking industry for molecular cooking. Molecular gastronomy or molecular cooking is a type of science that applies chemical and physical principles to the world of cooking. Molecular cooking is better known as an “innovative cooking style”, that combines psychological cooking skills with advanced technology.

This style of cooking uses rotary evaporators that non-heat evaporate liquids, that help to retain the volatile aromatics in foods that are usually lost through the process of heating. It has also been described as the ideal combination of experimental instruments and modern culinary.

In Chemistry Industries

But most commonly, the rotary evaporators are used in the chemistry-related environments for the purpose of gentle, yet extremely efficient removal of one or more solvents from a sample through the process of evaporation under a vacuum.

These chemical evaporators are made up of heating baths that come with rotating flasks. The liquid that is placed into the heating bath will distribute in a thin layer of film over the surfaces of the hot flask walls, which helps the liquid to evaporate easily. The rate of evaporation will be regulated by the temperature of the heating bath, the flask size, along with the distillation pressure. Other supporting factors include how fast the evaporation flask is rotating, and the coolant temperatures. In general, the principles of vacuum distillation are rotary distillation.