In simple terms, distillation is defined as a method of purifying a liquid by boiling it and condensing its fumes. In other words, that is, a liquid that, when sufficiently heated and cooked, captures the distillation process and evaporates the resulting hot fumes, and collects the condensed vapors.

This method of operation is not a chemical reaction but rather a means of physical unity or separation. In the modern chemistry laboratory, distillation is an essential requirement for the identification and purification of organic compounds. There are several types of distillation processes, some of which include molecular distillation. And in today’s article, we will tell you what is molecular distillation.

What Is Molecular Distillation?

Molecular distillation is a short-path distillation that works at a low-pressure vacuum. The whole process can be used for purification, concentration, and separation of the standard natural products. In most cases, it is used on thermally sensitive molecules. The process is the best for the above molecules due to its short exposure to high temperatures. If the molecules are in liquid form, the fluids get a free molecular flow, which converts them in the gaseous phase. At this stage, the pressure in the evaporation column is lowered, thus allowing evaporation to take place without pressure.

The working principle of molecular distillation

A pivoting scrubber pushes the material onto a warming surface, and the liquid of the material cautiously twists and leaves the warming surface, the material that comes off the warmed surface was quickly gathered by cooling the condenser, this strategy should confine contact material time and surface insulation.

In high vacuum conditions, short-separation distillation equipment through a material and liquid merchant, a scrubber are gathered with the goal that the material is equally distributed over the heating surface, lessening weight qualification that is conveyed to the static liquid surface material.

Later, the restlessness will disappear. The vapor will be dense in a separate condenser, and the liquid will either be expelled as a liberal object or sent to the corresponding stage. This strategy is a hot pack technology with the least amount of loot and the highest caliber. The short method of molecular distillation is the free fading of the liquid layer, which travels at low weight. Since there is no isolated air in the liquid, it is not possible to penetrate all the liquid during distillation in this way without spraying.

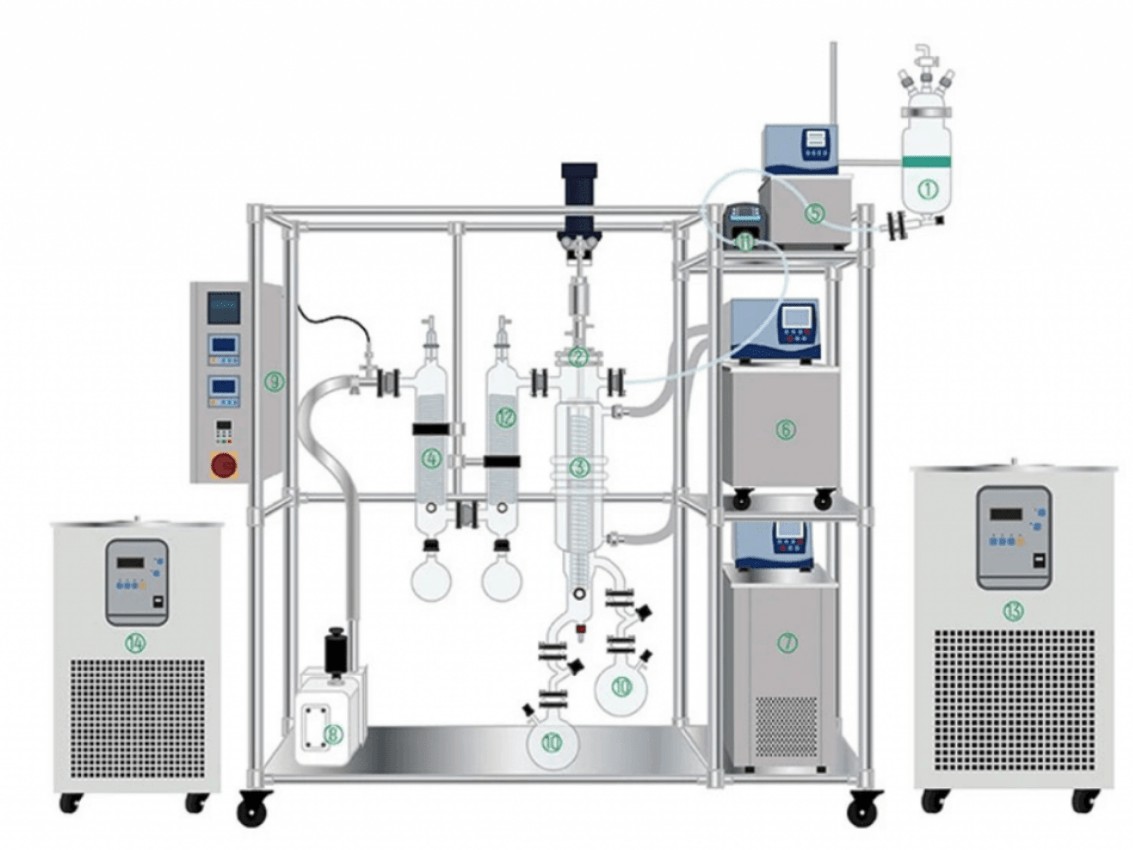

The Structures of WKIE LAB Molecular Distillation

- Control system

- Vacuum pump

- External condenser

- Magnetic stirrer

- Glass barrel with a jacketed internal condenser

- A heating column with a jacketed feeding vessel

- Feeding flask with manual jacketed feeding valve

- Cooling coils for cold molecule trapping

- Heating column

- Cooling and Heating condenser

- Continuous collection unit for distillate and residue

- Gear pump for constant and automatic feeding

- A cooling column with cooling coils

- Cooling column external condenser

The Applications of Molecular Distillation

Molecular distillation can be applied in different pieces of nourishment production. That is exceptionally reasonable for isolating warmth delicate and useful oxidation materials by separating and cleaning unsaturated fats. Some of the necessary applications include:

Obtainment of Amide

Fatty amide works as emulsifiers in physical work. It has anticorrosive responses and amines that are gotten from the reaction. Although the enrollment prerequisites for high product quality, however low performance, for instance, 98.5 percent quality, the recurrence of not over 88 percent, the use of molecular distillation rate up to 94 percent, It can reduce half of the waste.

Omega‐3 Fatty Acids

The extraction of omega – 3 unsaturated fats from fish fats includes the application of molecular distillation. The unsaturated fats are delicate to high temperatures. As a method for forestalling their harm, the specialists incorporate the use of this process. It process that consists of the use of the most recent gear, which subjects the unsaturated fats to the most fitting temperatures as a method for extracting the oils.

Extraction of Paraffin Wax

The process is used for the extraction of paraffin wax. Temperatures can be brought in the wake of lowering the weight down to accomplish the desired temperature for the evacuation of the paraffin wax.

Extraction of Monoglycerides

It is among the couple of processes you can use to get the monoglycerides from their raw materials. The strategy for molecular distillation targets lowering the temperatures, which leads to the successful extraction of the monoglycerides.

Lactic Acid Production

Too high temperatures can denature lactic corrosive. In the production of lactic corrosive, molecular distillation is applied to extract lactic corrosive from raw materials. It is used due to its ability to protect the quality of lactic corrosive in the extraction process.

Extracting Tocopherols From Soya Sludge

Tocopherols have low boiling focuses. They may be killed when the temperature goes excessively high. The application of molecular distillation has ended up being highly viable in the extraction of the compounds. It preserves the compound synthesis of the tocopherols in the extraction process.

Carotene Extraction

Carotene is a sort of nutrient used in nourishment. Today more people use healthy carotene rather than industrial carotene. The entire process of delivering industrial carotene needs triple molecular distillation; carotene-containing products can arrive at 40%.

Fat Extraction

Monoglyceride is widely used in the nourishment emulsion business. The measurable molecular distillation method is a run of the mill instance of that much-reported process study. The whole examination process, comparably, has a straightforwardly investigated molecular distillation process.

The most widely perceived get together techniques are to solidify the time of the primary oil arrangement of the presumably low substance of monoglyceride-containing products by 7 percent glycerol, and 35-40 percent glycerides.

Conclusion

In situations where the melting purpose of either compound is exceptionally high, the distillation unit’s contraption should likewise be furnished with twofold layered heated sleeves. These are required for its tanks, siphons, funnels, and valves. It is always acceptable to put resources into an excellent stirrer for your distillation unit’s evaporator.

Just as guaranteeing compounds are uniformly heated, a stirrer reduces the thickness of the fluid movies, quickens the condensation of fumes, and assists with parting residues from distillates. When buying molecular distillation hardware, search for proof of thorough research center testing. Before shipping, we will play out a series of tests to guarantee elite and prod