Food lyophilizer also referred to as freeze-drying is a process that entails freezing food at very low temperatures and then extracting liquid through sublimation; transferring water from solid to gaseous state skipping the liquid state. By converting water from solid to gaseous state without passing liquid state helps to boost shelf-life as well as the storage period of your food product. It is due to this reason that most people tend to find food lyophilizer useful.

In this article, we shall be discussing more on food lyophilizer and why it is vital in today’s world.

Why is Freeze-dried Food So Popular?

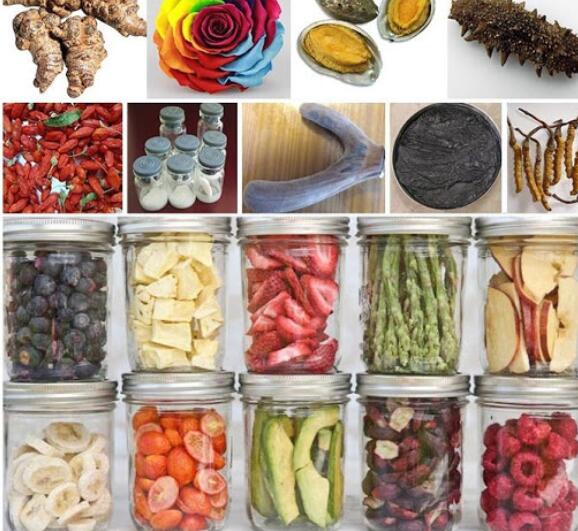

Freeze-dried foods are popular across the globe since it helps in boosting shelf life and storage duration significantly. Furthermore, the process involved in freeze-drying food is said to be ideal for packaging food and beverage products since it helps in maintaining the structural integrity and preserve food’s flavor for an extended period.

In addition to that, freeze-dried foods feature better aroma, bioactivity, and rehydration compared to products dried using different methods, especially fruits and vegetables. These are some of the aspects that have made freeze-dried foods popular across the globe.

Advantages of Food lyophilizer

Lyophilization is associated with several benefits in the food industry including;

· Improve transportation.

When water is removed from any food product, they become very light. As a result, it becomes easier to transport a large number of foods using affordable means of transports.

· Improved food quality.

Freeze-dried foods retain most of the nutritional qualities in the food. Furthermore, the food will improve its taste significantly and at the same time, retain its shape and size.

· Does not require refrigeration.

Once the food has undergone a lyophilization process, it can last for years and months without the need for refrigeration. In addition to that, these foods can be rehydrated very quickly compared to other dehydrated foods.

Advantages of Freeze-Dried Products

Freeze-dried products tend to have several advantages including;

· Supports consumer’s desire.

Freeze-dried products have been designed to retain nutritional value compared to other preservation methods. This helps in supporting consumer’s desires.

· Sweet aroma.

All freeze-dried products feature intense flavor and aroma, which closely resembles the profile of raw material.

· Nutrient dense.

Freeze-dried products tend to rich in nutrients since they retain their nutritional qualities for an extended period.

Major Types of Food Lyophilizer

– Bench-top lyophilizer

A bench-top lyophilizer features a vacuum system, refrigeration system, electrical instrument control system, and a heating system. The primary components of a bench-top lyophilizer are condenser, drying oven, vacuum pump, refrigeration unit, and heating/cooling devices, among others. This lyophilizer works by freezing dried food to below the triple point temperature of the water and then sublimates it under a vacuum condition. These types of lyophilizers are ideal for handling small volumes. A bench-top lyophilizer features a small footprint and light in weight; in addition to that, they are designed to handle samples that are lightweight.

– Floor lyophilizer

Floor lyophilizers are equipped with the same features as a bench-top lyophilizer. This means that they feature the same functionality and are ideal for drying different food products. However, floor lyophilizers are highly essential when it comes to handling large scale applications. This is the primary difference between a floor lyophilizer and a bench-top lyophilizer.

– Which to choose?

Choosing the best lyophilizer between bench-top lyophilizer and a floor lyophilizer will highly depend on your production load. As previously stated, bench-top lyophilizers are ideal for handling small volume while floor lyophilizers are beneficial for large scale production. Therefore, floor lyophilizers will be best for you when handling large-scale production.

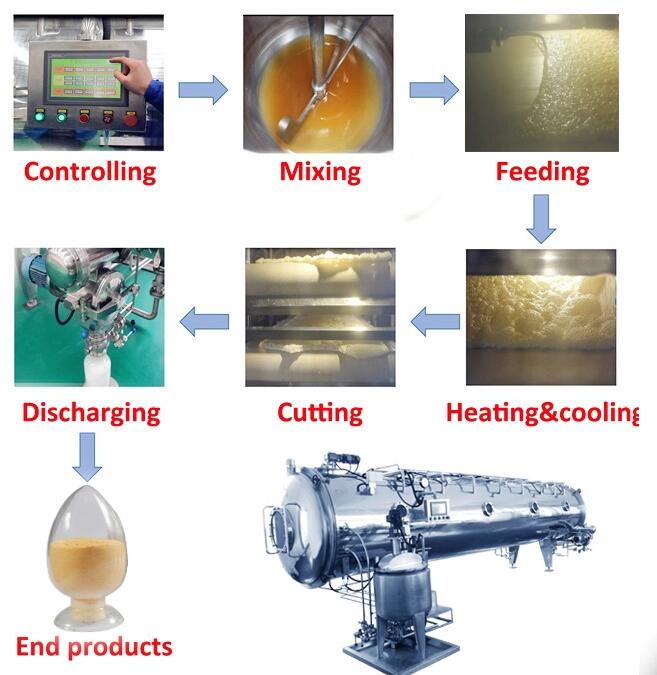

The Freeze-dried Food Process

The freeze-dried food process often varies in details of time, temperature, pressure as well as intermediate steps from one product to the other. However, the generalized freeze-dried food process is as follows;

Test and preparation

Before commencing on the freeze-drying process, food is first assessed for any contamination and purity. For fruits and meats, along with other edibles, can test for spoilage and bacterial counts. In addition to that, some types of foods such as meat and seafood need to be cooked prior to freeze-drying; however, for fruits and vegetables, you will cut them into small pieces and don’t need to be cooked. All that is required of you is to wash your fruits and vegetables before freeze-drying them.

Freezing process

Once you have your food products ready, you will spread them out on a flat metal tray. For foods that have been pre-cooked prior to the freezing process, you will need to pre-chill your tray to help in preventing thawing while handling. For liquids such as coffee, pre-brewed coffee should be poured on a shallow pan. Once this is done, you will put your food in the freezer with temperatures as low as -40 degrees Celsius. Your food will quickly freeze in this extreme cold.

Drying

Once you are done with the freezing process, you will take your food from the freezer into a drying chamber. For liquids such as coffee, you will first ground-up your frozen coffee into small particles in a low-temperature grinder. The drying process involves a sublimation process. This means that the frozen water available in the food will be changed into a gaseous state without passing the liquid state.

In this drying chamber, this process is accomplished by getting rid of air using a vacuum pump, reducing the pressure to approximately 0.026 psi. The food’s temperature will be raised to 38 degrees Celsius by microwave heating. When air is removed from the chamber, the pressure in the chamber will be below the threshold in which water can exist simultaneously in liquid, solid, and gaseous state; usually, this threshold is referred to as the triple point of water.

When the pressure falls below this threshold point, the heat will force the water trapped in your food to sublimate, leaving your food dry. The dried food will then be filled with small voids like sponges, where ice crystal was once present. This makes it easy for water to reabsorb when you are preparing your food for consumption; however, your dried food will retain its original size and shape. Usually, solid and semi-solid foods such as meats and soups will take long to prepare 12 hours; on the other hand liquids such as coffee will take 4 hours.

Blending and sizing

When you remove the dried food from the drying chamber, it is tested for purity and moisture content. Some pieces of food might be grounded to smaller sizes or might be reduced to fine powder while others can be screen and separated by different sizes. You might as well consider blending two different products to meet your specifications.

What Is the Freeze-drying Sublimation Process?

Sublimation is a process where ice changes state to vapor without going through the liquid phase. In freeze-drying, sublimation is used in draining water from food products to help increase its shelf life and storage period significantly.

How Does Food Lyophilizer Work?

Food lyophilizer is a sophisticated machine that facilitates the lyophilization process. The lyophilization process is a relatively pricy and costly technique that has been used in preserving astronauts’ food among other essential food products. The food lyophilizer works by removing water through sublimation as previously state. The sublimation process is often used in preserving perishable materials, extending its life, or makes the product more convenient for transport. The food lyophilizer works by freezing food and then reduces pressure before adding heat to the food to help in sublimating the frozen water.

The most exciting part is that the act of food lyophilization is an ancient process practiced for several years. Over the centuries, food lyophilization has become a part of food industries to help in food storage and extending the food shelf life significantly.

How Many Properties of Freeze-dried Products?

Usually, Freezer-driers feature four basic properties which are condenser, vacuum pump, drying chamber, and a source of heat. However, within the last few decades, the properties of freeze-dried food have increased significantly. In fact, the drying research and developments have extended beyond their limits when it comes to the chemical as well as mechanical engineering approach of mass transfer and heat.

Freeze-dried has been used in preserving food with a small emphasis on a multi-dimensional attribute. The recent trend is to come up with freeze-dried foods while maintaining its quality including texture, flavor, convenience as well as functionality with an increase in nutritional content to help in increasing nutritional content and reduce anti-nutritional toxins or factors.

Nowadays, freeze-dried foods have extreme focus when it comes to maintaining bioactivity as well as food’s structural functionality.

How Are Food Lyophilizers Different from Industrial Lyophilizer?

The main function of a food lyophilizer is to freeze dry food products only hence helping in extending their shelf-life while maintaining its nutritional value. Food lyophilizer is well-known when it comes to producing foods with high-quality compared to all other drying techniques. This is because food lyophilizer helps to maintain the structural integrity of food, allowing it to preserve both flavor and nutritional value of food for an extended period.

On the other hand, an industrial lyophilizer has been designed to freeze-dry several products, including chemicals, foods, dairies, vaccines and documents, among other vital products. Unlike food lyophilizers, industrial lyophilizers have been designed to handle large scale productions. Furthermore, they are equipped with several essential features that are omitted in a food lyophilizer.

Food Lyophilizer Vs. Laboratory Lyophilizer

Application

Food lyophilizers are often used to freeze-drying food for preservation in a small volume. On the other hand, laboratory lyophilizers are used in preserving samples for storage or change the state of the sample for research or testing. Furthermore, an industrial lyophilizer has been designed to handle an array of substances, including pharmaceutical products, biological products and chemicals, and blood, among others.

Capacity, structure, and size

Most food lyophilizers have been designed for home use, and they are often small in capacity weighing approximately 1 to 5 kgs. Food lyophilizer does don’t feature high requests; this means that it features a very simple design with the essential parts required in a lab lyophilizer missing. When it comes to the lab lyophilizer, size of the essence; a lab lyophilizer is equipped with sufficient capacity since it is designed to handle a more significant load compared to a food lyophilizer.

Vacuum and temperature

Vacuum, temperature, and time required to reach a target parameter are among the noteworthy aspects between these two lyophilizers. For the food lyophilizer, it is often shelved without freezing function and often feature a temperature range between -20 and -30 degrees Celsius. Furthermore, they are equipped with a vacuum reaching 50Pa, which often is considered enough; however, it takes an extended period.

On the other hand, a lab lyophilizer shelf often requires a combine freezing and heating functions and a temperature that ranges between -50 and +70 degrees Celsius along with a raise/reduce the efficiency of 1C/min. A lab lyophilizer features a condenser that reaches -55, -85 or -120 degrees Celsius; this makes it ideal for handling different types of chemical materials. Moreover, the condenser is capable of reaching -40 degrees Celsius within 60 minutes or faster. A lab lyophilizer has featured a vacuum with 5Pa.

Price

When it comes to cost, a food lyophilizer is much more affordable compared to a lab lyophilizer. This is because several essential parts are omitted from a food lyophilizer that is considered of great value in an industrial lyophilizer.

History of Lyophilization in the Food Industry

Richard Altmann first developed lyophilizer; however, the process was not primarily used until the late 1920s and 1930s. The early use of lyophilizer in the food industry was purposely for military rations and developing foods for astronauts. An increase in shelf-life made the process suitable for both NASA and unique military requirements.

By rehydrating, the meal meant that hot food would still be provided unlike early attempts of produced tube food for the astronauts. Nowadays, lyophilizer is used in an array of common food products which include vegetables, fruits, coffee, and meats as well as meat substitutes. Furthermore, the process is used in creating food products with nutrients locked in for future use.

The Future of Freeze-drying in the Food Industry

Freeze-drying has been used for decades in preserving foodstuffs along with other biological materials. In the early 1930s, industrial freeze-drying was first developed as a way of preserving surplus coffee. In recent decades, freeze-drying has been expanding at an incredible rate to a point where nowadays it is used in producing more than 400 different foodstuffs along with essential pharmaceutical products. The future of freeze-drying looks brighter with the new freeze-drying process promising to eliminate all drawbacks associated with it.

Final Verdict

Food lyophilization is an ancient practice that was used to help in increasing food shelf life. Nowadays, the lyophilization process has advanced significantly with all freeze-dried products retaining their nutrient, shape and size. This process is essential when it comes to storing food products for an extended period without the use of a refrigerator. As we conclude, we hope that this article has been of great benefit when it comes to understanding food lyophilizer better.